As the Internet of Things becomes increasingly popular, more companies are looking to monitor and track their assets across the world. And many want the ability to sell their wireless products in global markets. Maybe you have been solely operating in North America for a long time and you want to take the next step and adapt your existing successful product for Europe. Getting a wireless product certified for global deployment can be a daunting prospect.

We understand. At Digi, we work through the certification process with our own products, and support our customers through that process all the time. For example, our

SmartSense by Digi team partnered with a large European-based customer and was then challenged with expanding their suite of smart cellular gateways and sensors to be sold and operated in the EU region. We made it happen.

Digi WDS has supported hundreds of customers through the global certification process when they wanted to expand to international markets. We developed this article to help you establish a baseline knowledge surrounding global cellular products and create an action plan. We can also support your requirements through any aspect of that process.

Going Global with Your IoT Product or Deployment

One thing that is important to understand is that “global” does not mean "everywhere."

There is no such thing as a "global certification." Each product must be evaluated for certification requirements in each region where it will be sold, as there are different cellular bands, different certifying bodies, and different requirements by region. A cellular product may or may not work outside its country of purchase without being certified for sale elsewhere.

Going global is a very long and arduous process with lots of rules, forms, and governments to work with. Therefore, a set of well-defined use cases for the cellular product will determine what “global” means in the context of the product.

If your company is developing a new product and envisions selling globally, here are a few steps your development team can take:

- Take “baby steps” – Get to market quicker by selecting the region(s) with the highest potential and focusing on developing for those regions first. After the initial release, follow up with a staged rollout over all the other regions. Compiling certification paperwork for different regions is time-consuming and costly, so a staged rollout helps balance the staff workload.

- Avoid complexity – Give weight to hosting multiple SKUs since off-the-shelf cellular radios frequently come in a family of products with the same size and form factor. If the multiple-SKU route is right for your company, this is best accomplished by developing a suite of variants catered to each region.

Addressing Multi-Region Use Cases

If the product will travel a lot between regions (for example, tracking on intercontinental freighters), the design requirements rule out large suites of SKUs as well as the ability to disperse certification work over a longer timeframe.

Use cases that require multi-region usage also bring new challenges: cellular radio modules have to have available bands in the operating regions, further narrowing the available module options. Regardless of the product’s use cases, it is important to set those use cases concretely so further research and planning can start.

Recommended Development Plan for a Global Cellular Product

Day one planning for a new cellular product should address three things:

- The product’s data rate

- Data usage

- Regions of operation

Data Rate and Usage

Data rate and usage determine the cellular category (Cat) going into the product. Higher Cats allow for larger amounts of data to be transmitted at faster data rates. This comes at the trade-off of higher power consumptions and more expensive radio modules.

Regions of Operation

Product regions are extremely important from a development side. Radio modules come in families, so to simplify the circuit design and reduce costs, it is best to stay within that family. Hence, region choice determines the viability of each module fabricator.

In addition, common operating frequencies may exist between countries as well, so setting operating regions informs the development team of the product’s antenna design.

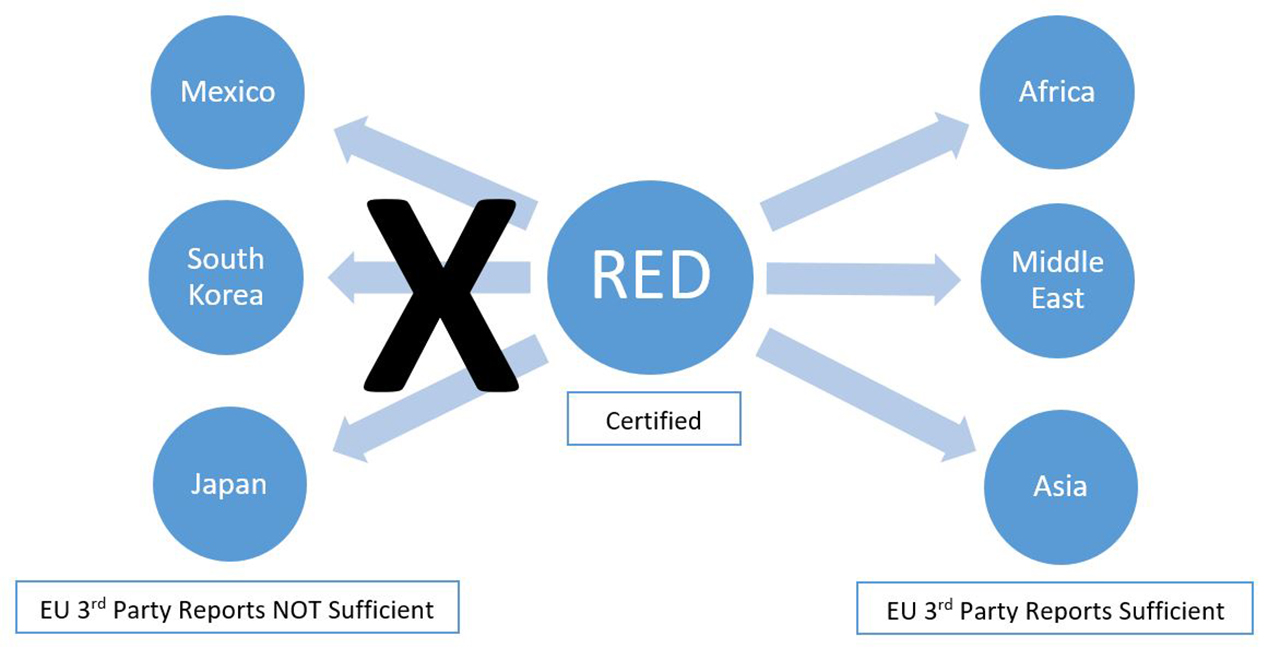

There is also the matter of wireless certification. Many regions have common certification tests, so choosing regions provides a realistic understanding of the timeline as well as how much paperwork needs to be filed to regulatory boards. For example, the United States and Canada dole out FCC ID and IC numbers, respectively, but behind each certification is effectively the same set of tests. Likewise, the European Union’s Radio Equipment Directive (RED) sets testing standards for the EU, but additional countries, primarily those in Africa, Asia, and the Middle East, also accept products which conform to RED.

Passing lab tests for these two certifications allows products to be sold in more places than just the US and EU. However, be aware countries with more developed markets such as China, South Korea, and Mexico may require additional tests on top of the EU or FCC-mandated ones.

Equipment Selection

Once the data rate, data usage, and operating regions have been addressed, take stock of existing resources. Placing a cellular product on the global market is a huge step, so be certain you consider the following points before moving forward:

- What improvements could be made from existing products? Introducing a variant of an existing product is a no-nonsense way to enter a new region. However, do not start with existing products with little to no documentation – it would be better just starting from scratch.

- What will be purchased off-the-shelf or developed in-house? Components like shields come in easy off-the-shelf sizes, so to reduce costs it is important to keep sensitive radio components to those sizes. Antennas also come off-the-shelf but with the right expertise, designing a custom antenna may be more cost-effective.

- Have you budgeted for certification? For an FCC ID and CE mark, the fee alone for the two certifications can be 25,000 USD or more. That cost doesn’t cover the hours for filing the paperwork, ensuring the packaging is right, use of the testing chambers at an ISO/IED 17025-compliant test lab, and other related costs. Failures are common, so it is also important to plan for design changes in those cases. (Note that Digi WDS can often save these excess costs by ensuring the product is designed to meet certification requirements. Consult with our team to learn more.)

- Do you have the expertise to draft a design verification test (DVT) plan? With the cellular market operating on a global scale, competition is fierce, so it is important to get a product right on the first release. Planning for a large number of new regions increases the number of tests and the complexity of the DVT before the product is ready for launch. If your engineering team is not very familiar with all the different certification tests, consult a certification or homologation engineer from a local consulting group or test lab.

- Have you set aside time and money for certification pre-testing? Even companies with a great track record in wireless products need to entertain the thought they might not get it right on the first board spin. What is also worth mentioning is that an antenna prototype that works on an unpopulated ground plane may not work on the end product. Pre-testing a cellular product at an EMC test lab is not free, but it is certainly less expensive than filing a full certification packet with a faulty board and bad data.

- How will the manufacturing plant test the product? Be mindful that if manufacturing will take place in a different country from research and development, it will be significantly more difficult to verify the quality of the product as it comes off the line. For example, cellular products designed for only North America, but manufactured in China, might not connect to a live network right off the manufacturing line. Since China and North America use different LTE bands, it might be impossible to run real-world tests on the manufacturing line. Therefore, it’s best to keep an open line of communication between supply chain and R&D so these things are addressed before it is too late.

Final Notes

Polling existing documentation from past products as well as people with expertise in design verification makes it easier to set benchmarks for product development. If neither of those resources exists in-house, consult other white papers from leading companies in the industry or hire a consulting firm.

Digi has developed deep expertise in our 30+ years of business in connected devices. Although SmartSense by Digi is the most recent product line to receive a rework treatment, the rise of 5G has made us revisit all of our existing cellular products for updates to meet our global organization's goals.

It is imperative companies looking to enter this space have talent on their development teams familiar with cellular technology and how to go global with it. Digi WDS is a world class expert in this area. Partner with Digi WDS and we will be there from the start of your program through production and launch to ensure proper planning and budgeting while steering clear of all the common mistakes.