If you’ve followed news related to product development, predictive analytics or

Internet of Things-based environmental monitoring, you’ve more than likely heard the term “digital twin” or “digital twin modeling” in recent years. But what is a digital twin exactly? In simplest terms, it’s a virtual representation of a physical object, device or structure that exists in the real world.

There’s much more to this innovative technology, and we’ll be diving deep into the implications of its rapidly evolving use cases in manufacturing, healthcare and supply chain management, among other industries. But first, it’s important to understand what’s led to widespread interest and investment in digital twin development and the use cases seen today.

Digital twins have existed since the 1960s, conceptually, and more broadly popularized starting in 2002 — only recently has innovation in this area exploded. As digital capabilities have become increasingly central to customer experience and operations,

data-driven insights have become the force driving innovation and value generation.

As a result, digital twins are beginning to optimize the development and performance of products and processes. Let’s explore how.

What Is Digital Twin Technology?

Let’s start with a digital twin definition. Digital twins are virtual models based on real-time data collected using connected sensors. These virtual twins, as they’re sometimes called, are designed to mirror real-world objects, machines and processes — enabling system designers and technical staff to simulate the physical properties and performance of the real-world system.

The process of digital twinning creates a digital representation that can be updated as the physical version changes over time, whether it’s affected by environmental conditions or repaired. To capture these changes, the object needs to be fitted with IoT sensors designed to capture and transmit data about the object or device’s physical characteristics and performance.

This information can include the object’s shape, energy usage, material stress levels, temperature or performance. Then, the information gathered is processed and used to create or update the virtual representation.

Once created, digital twins can be used to run two types of simulations:

- Present-based: Visualizing how the physical object would react if current conditions were modified.

- Future-based: Running predictive simulations to show responses to future conditions.

What Are the Types of Digital Twins?

Overall, the way that digital twins are created — using IoT devices and software — is fairly consistent no matter what type of object, equipment or process is being digitally represented.

The complexity of a digital twin can range significantly, as the amount of data needed depends on the intended use for the virtual representation. Often, organizations will create an initial prototype of the digital twin to determine how to best incorporate all the data needed.

There are three functional types of digital twins commonly used:

- Status twins: Used for monitoring the physical condition of physical objects and equipment

- Operations twins: Used to allow users to adjust operating parameters based on linked actions or workflows

- Simulation twins: Used to predict how the object or device will respond to operational conditions in the future, which is helpful for predictive maintenance and product development

How Is Digital Twin Technology Used?

Because there are so many variations of digital twin design, there are also numerous ways to categorize the designs and functions of these virtual replicas.

For instance, an organization might need all these system architectures of virtual twins:

- Discrete digital twins: Used to visualize, monitor and analyze a single device

- Composite digital twins: Made up of multiple discrete digital twins to represent a device or process with multiple components

- A Digital Twin of an Organization (DTO): A highly complex representation of the components and interactions of an entire organization

Then, for any of those three digital twin system architectures, the way that data can be used can fall into five categories or levels:

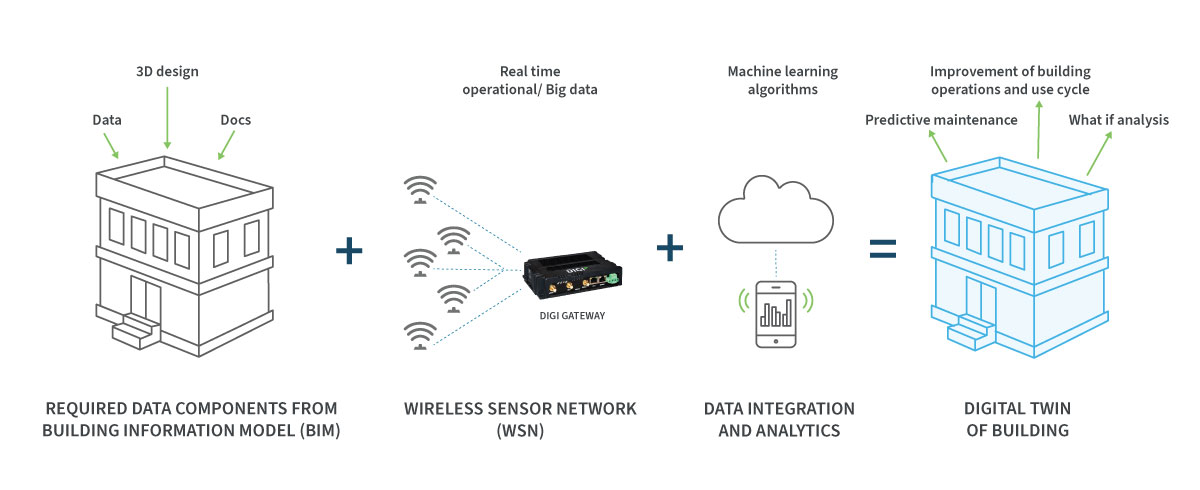

- Descriptive twins are virtual representations of an object or device that can be edited and analyzed with 3D modeling of building information modeling (BIM) software.

- Informative twins take digital twinning a step further, and take physical and operational data from IoT sensors on the object or device of interest and update the virtual replica in real time to match its real-world counterpart.

- Predictive twins combine real-time data used to create informative twins with additional contextual data and predictive analytics. This allows modeling and present-based simulations that can identify or predict issues with performance or structural integrity.

- Comprehensive twins use more advanced modeling to predict how the object or device presented will respond to future-based scenarios that haven’t yet occurred. The prescriptive analytics used for this type of digital twin can inform recommendations for what steps to take next (e.g., maintenance, product design).

- Autonomous twins also use future-based simulations, along with advanced algorithms, to make artificial intelligence and machine learning (AI/ML)-driven decisions to respond to changing environmental conditions based on the past performance or physical condition of the object.

What Industries Use Digital Twins Today?

Digital twin technology can be used to create business value in a variety of ways. It all depends on the variety of data sources, the functional type (i.e, discrete, composite or DTO) and the level (i.e., descriptive, informative, predictive, comprehensive or autonomous) of the virtual representation created.

Digital twin technology can be adapted to benefit organizations in almost every sector, and some of the industries that use digital twins today including in multiple vertical spaces where Digi provides technology solutions for IoT product development, networking, automation, predictive analytics, and the future of Industry 4.0:

- Manufacturing: This technology can be used to visualize, monitor and improve manufacturing processes on the factory floor. With comprehensive or autonomous digital twins, organizations can even identify ways to avoid asset damage and lost revenue in the future.

- Healthcare: Currently, digital twins are most commonly used on three types of healthcare use cases:

- Simulating and testing different organizational and care delivery models

- Training for invasive surgical procedures and

- Genome, lifestyle and physiological modeling to develop personalized medication.

- Aerospace: Digital twinning was actually first used in aerospace engineering, and now engineers in this field can better use predictive analytics to test components and parts for failure without risking costly equipment or safety.

- Automotive: In addition to improving standard manufacturing in the automotive industry, digital twinning is also being used to help develop autonomous vehicles. Self-driving cars require IoT sensors that gather data on the condition of the car and its environment. Virtual replicas can be used to test the vehicle’s function in various scenarios.

- Construction and engineering: Digital twins of buildings can be used to design building architectures that are better suited to their environment and to monitor existing buildings for material failure, reducing the risk of collapse and supporting predictive maintenance.

General Use Cases for Digital Twin Technology

Before an industry-specific use case can be implemented, developers and data scientists need to work together to determine exactly what components need to be represented. And the same real-world object could require dramatically different data inputs depending on the end goal of the digital twin model:

- Materials or components

- A whole asset or product

- A system

- A process

Let’s explore three broad categories of use cases that digital twin technology can help accelerate and improve.

Product Development and Design

Organizations invest heavily in product development and design to remain competitive, especially in industries like automotive, pharmaceuticals and manufacturing, among others. Also, companies are always looking for ways to develop products faster without sacrificing quality and product-market fit.

Digital twins can help improve product development and design by allowing product teams to:

- Stress test materials using virtual simulations

- Incorporate early feedback on physical prototypes into virtual representations

- Create multiple product versions at once to test and gather feedback

Process and Operations Optimization

Today’s organizations also want to optimize their internal processes and operations — whether that’s on the factory floor, their supply chain or their enterprise resource planning. Creating digital twins can help companies better:

- Analyze production results and plan ways to improve productivity and efficiency

- Identify areas of waste and lost time and test simulations on how to reduce them

- Implement predictive maintenance or autonomous operations that protect valuable equipment, systems or processes from costly damage or downtime

Environmental Monitoring and Disaster Response

By developing digital twins of manufacturing, agricultural or supply chain processes, organizations can more quickly respond when environmental conditions or equipment failure exposes their site and their staff to unsafe conditions or puts the local environment at risk. Alerts enabled with more complex digital twins can also help site managers and employees respond quickly and effectively to reduce risks to public health and environment safety when disaster strikes.

What Is the Value of Digital Twin Technology?

The global market for digital twin technology is expected to continue to see explosive growth in the coming years, with a projected compound annual growth rate (CAGR) of 31.7% from 2022-2027. That’s because using digital twin models not only increases productivity and efficiency, it also helps accelerate innovation.

Increasing Productivity and Efficiency with Digital Twins

There are endless scenarios in which creating digital twins can provide insight and value. With advances in AI modeling and IoT-enabled data collection, companies can better predict how products, equipment and processes will react to new environmental conditions or stressors.

Instead of creating a costly prototype to test or reacting after an incident occurs, companies can explore the potential effects in a virtual environment. That results in speed to value at a significantly lower cost — which is exactly why digital twinning has rapidly grown in recent years.

Using Digital Twinning to Accelerate Innovation

Although digital twins are used to represent what already exists, in reality, they are one of the best avenues to reaching the innovation that’s yet to come. Creating digital twins allows product designers, developers, engineers and data scientists to collaborate and envision future versions of a material, product or process while also simulating various scenarios to evaluate performance.

As a result, digital twin technology can help organizations determine which paths to take to reach innovation and deliver value faster, with less time, effort and cost.

Digital Twinning and the Future of Smart Cities

Today, companies in every industry are highly invested in finding green technology solutions that reduce their environmental impact and improve their productivity, while cutting operational costs. Companies need IoT-enabled solutions to support many of the most effective sustainability solutions that can help them reduce their environmental impact and avoid or respond when disasters occur.

Monitoring how equipment and material respond to various environmental conditions not only helps with predictive maintenance, but it also helps improve overall environmental monitoring. In the future, system-level digital twins can help accelerate the development of smart cities that can be equipped with IoT-enabled sensors and optimized to use public resources in a more efficient, cost-effective and environmentally friendly way.

There are still challenges to overcome to realize this future. Organizations need to find solutions that help them:

- Efficiently gather data from a variety of sources at distributed remote sites

- Maintain consistent data standards for ease of integration and analysis

- Coordinate data sharing across organizations and municipalities while ensuring security

But with the right remote infrastructure management solution and secure IoT devices, modern organizations can readily take advantage of the productivity and innovation benefits that digital twinning applications offer.

How Digi Solutions can bring a digital twin model to life

Digi IoT solutions connect the physical world to the digital world, providing real-time machine and sensor data from IoT devices to feed this data into AI/ML models and algorithms that build digital twins.

Learn more about how Digi solutions and Digi Professional Services can help your organization bring digital twins to life, helping you improve your organization’s products, processes and systems while accelerating your path to innovation by following our blog or reaching out!

Next Steps