Whether it’s perishable foods, sensitive pharmaceutical products, or even latex paints, manufacturers and transportation firms must carefully ensure their goods remain in strictly controlled climates from farm or factory to retail shelves. CapTemp’s innovative NIDUS is the first and only remote monitoring and reporting solution fully certified to comply with Europe’s stringent EN12830:2018 and WELMEC 7.2 standards.

The Growing Importance of Food Safety Across the Supply Chain

From fish and meat to dairy products and other perishable food products, manufacturers and transit companies are under greater scrutiny than ever to ensure — and document — that sensitive goods remain within prescribed temperature ranges at every step. In Europe, food safety has received an even greater emphasis, thanks to the EN12830:2018 standard, part of the “WELMEC 7.2 framework for temperature recorders for the transport, storage, and distribution of temperature-sensitive goods.”

CapTemp, a Portuguese specialist in the development of monitoring systems and remote-control solutions, has risen to the challenge, becoming the first European company to create a cloud-based cold chain automation solution to record temperatures and earn certifications that confirm it meets the stringent new standard.

According to Carlos Domingues, CapTemp founder and CEO, it’s a challenge the company has pursued for more than 10 years. “Food safety has been a concern for many years, of course,” he noted. “In 2011, we leveraged some of our previous work in school climate-control to create the first software-based temperature recorder in Portugal to meet European standards.”

Cold Chain Automation

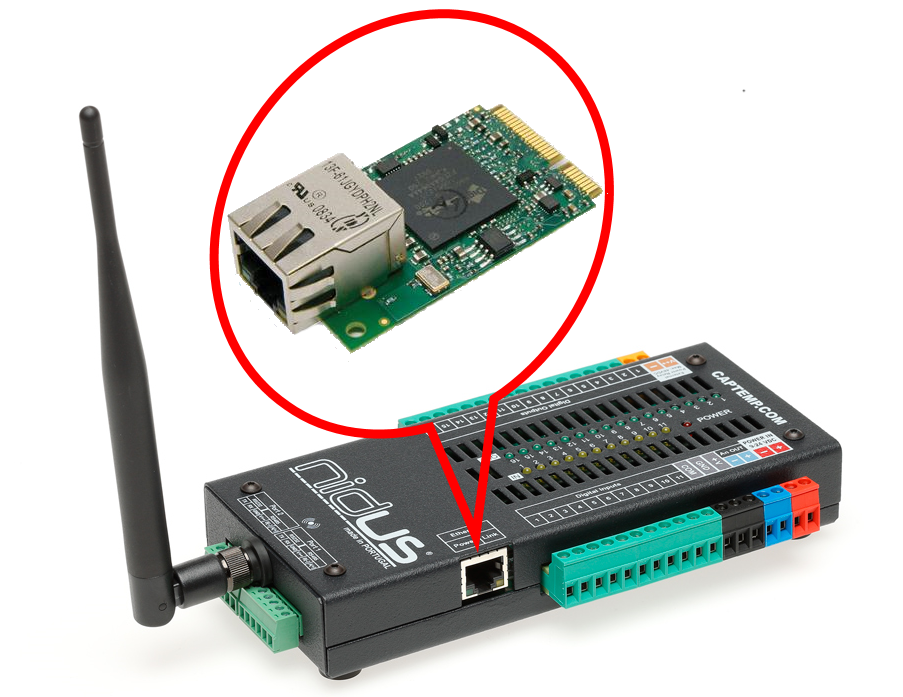

That product — NIDUS — leverages the ultra-compact Digi Rabbit MiniCore RCM6760 embedded module, which is directly integrated into CapTemp’s proprietary PCB design. The Rabbit MiniCore RCM6760 provides a cost-effective, high-performance, web-enabled device server with up to six serial ports, configurable I/O, and control features such as PWM.

That product — NIDUS — leverages the ultra-compact Digi Rabbit MiniCore RCM6760 embedded module, which is directly integrated into CapTemp’s proprietary PCB design. The Rabbit MiniCore RCM6760 provides a cost-effective, high-performance, web-enabled device server with up to six serial ports, configurable I/O, and control features such as PWM.

The RCM6760 is fully programmable in Dynamic C, an ANSI C-compatible development environment that includes a royalty-free TCP/IP stack and Wi-Fi support. Various protocols such as Zigbee and Modbus are also supported to reduce development costs and time-to-market. The RCM6760 provides connectivity and control to numerous devices, allowing for greater design flexibility without sacrificing features and cost.

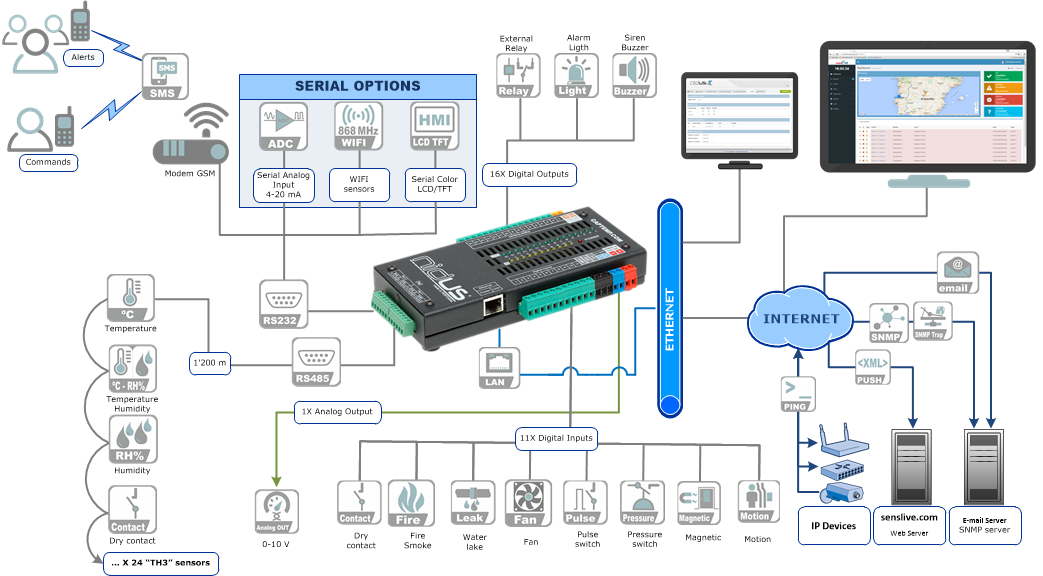

“We’ve been longtime users of Digi’s Rabbit modules,” said Domingues. “We have deep experience with this platform and rely on it for 900 MHz wireless and RS-485 cabled connections to controllers and sensors. One of our clients — a major chicken producer — realized they could use our solution to control more than just temperature, and so we added humidity, oxygen, and carbon dioxide sensors — all communicating through the Digi Rabbit module.”

Taking Cold Chain Automation to the Cloud

In 2018, the EU expanded its standard from merely recording temperatures of foods to monitoring temps in pharmaceutical storage and transport, replacing the existing hodgepodge of CFR-11 and U.S. FDA standards. “It was a timely move, given that we were unknowingly about to face a global pandemic,” said Domingues. “The operative phrase is now ‘sensitive goods,’ and that can apply to many materials — not just food and vaccines. For instance, if you transport paint in a truck, the environment must be 14 degrees Celsius. If you don’t comply and the cargo is damaged, you’d be ineligible to collect insurance proceeds. CapTemp helps companies diligently meet this strict standard for environment monitoring.

“Our system collects those readings — in factories, trucks, and warehouses — sends it to a controller through the cloud and stores it in a database. At no point can the data be manipulated. Our gateway brings it all to the cloud, and then we can provide it to the customer through our SaaS web portal/SCADA server called SensLIVE with digitally signed and timestamped reports and graphs.” These reports can show a range of important metrics: power consumption of compressors, gas consumption, water usage, or even temperatures and windspeeds near solar panels (which can reduce panel fires and insurance claims).

According to Domingues, CapTemp remains committed to Digi Rabbit embedded modules. “Digi Rabbit embedded modules have been extremely reliable for us,” he said. “In the 10 years we’ve been using them, we’ve never had to change one module for any client. They’re a safe choice with a very low total cost of ownership.”

Moving forward, the company foresees continued growth across the continent. “We’re still the only company to offer a temperature monitoring solution that meets these strict European requirements,” said Domingues. “That gives us important advantages that we think position our firm very well in the coming months and years.”