Industrial systems are no longer confined to the walls of a single facility or tied to fixed networks. They stretch across oil fields, span rural water utilities, and manage operations in rugged manufacturing environments. As infrastructure has evolved, so too must the way we control, monitor, and secure it.

The old model — centralized, latency-prone, and reliant on public IPs — is reaching its limits. And the consequences of sticking with legacy architecture are real: delayed responses, higher costs, security vulnerabilities, and unnecessary downtime.

The solution? Edge intelligence — and it’s here now.

Redefining Control at the Edge

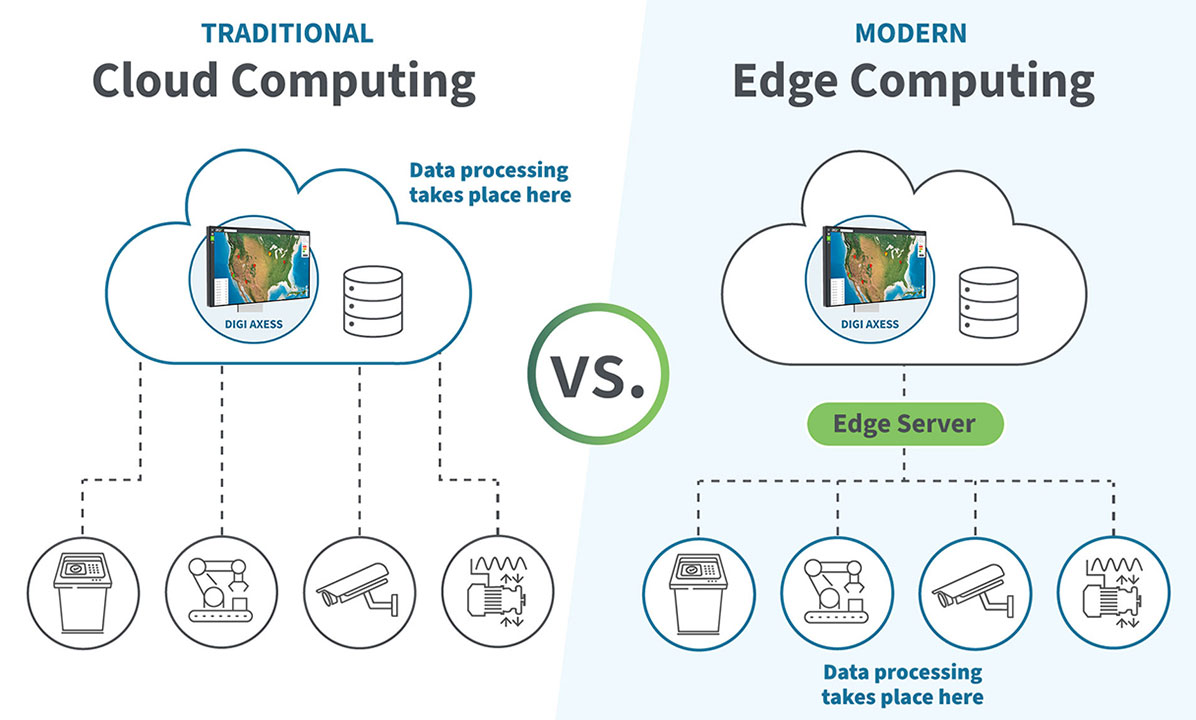

Edge intelligence means placing computational power and decision-making directly at the site of operation. Instead of routing every input or signal to the cloud or a central data center for processing, smart controllers at the edge analyze data locally, act instantly, and send only essential information upstream.

Edge intelligence means placing computational power and decision-making directly at the site of operation. Instead of routing every input or signal to the cloud or a central data center for processing, smart controllers at the edge analyze data locally, act instantly, and send only essential information upstream.

This shift isn’t just about speed. It’s about autonomy, resilience, and cost-effectiveness — especially in industrial environments where every second and every packet counts.

Digi Z45 Industrial Controller embodies this shift. Engineered for remote deployment and local logic execution, it processes critical events at the source, enabling:

- Instant responses, even in sub-second timeframes

- Operational continuity during network interruptions

- Local filtering of noisy or redundant data

Whether it's shutting down a valve before a rupture or adjusting machinery mid-cycle to prevent product loss, the Z45 ensures that control remains where it belongs: on-site and in your hands.

Centralized vs. Distributed: What’s the Real Difference?

In the past, central control systems were sufficient — mostly because edge devices lacked the intelligence to do anything more than relay data. But that model was built for a different era. Today’s industrial environments demand faster response times, higher reliability, and airtight security.

Let’s break down the key differences:

|

Characteristic

|

Centralized Control

|

Edge Intelligence

|

|

Latency

|

High – Cloud roundtrips

|

Low – Local processing

|

|

Network Dependency

|

Total – Needs stable link

|

Minimal – Works offline

|

|

Resilience

|

Vulnerable to outages

|

Always-on availability

|

|

Scalability

|

Limited by infrastructure

|

Easy to replicate

|

|

Security

|

Public IP exposure

|

Private network access

|

It’s not about choosing between edge and cloud — both are essential. But in scenarios where speed and control are critical, edge clearly takes the lead.

Enter Digi Z45: Built for Today’s Industrial Demands

Digi Z45 isn’t just a rugged PLC. It’s a fully modern controller, combining industrial-grade design with flexible I/O, multi-protocol communications (serial, Ethernet, cellular), and embedded IEC 61131 logic for fast, reliable automation.

Its compact footprint makes it ideal for harsh and space-constrained environments, while its configurability allows for easy deployment across diverse use cases — from pump control in water utilities to asset monitoring in remote oil fields.

Most importantly, it doesn’t need a public IP. That alone eliminates a major attack vector and simplifies network setup. But that’s only part of the picture.

Securing the Edge Without Complexity: Digi Axess VPN

Connectivity at the edge opens doors — but without strong access controls and encryption, it also creates risk.

Digi Axess VPN solves that problem by providing secure, always-on access without the need for static IPs, complex firewall rules, or traditional VPN headaches. It’s a cloud-managed, private VPN designed specifically for industrial edge deployments.

Here’s what it offers:

- Private network access with zero public exposure

- Seamless setup and scaling via the Digi Axess platform

- Encrypted tunnels for secure communications

- Cellular backup, ensuring uptime even when wired links fail

- IT-friendly remote diagnostics, without additional VPN appliances

With Digi Axess VPN, your Z45-enabled devices are easy to reach and impossible to compromise — giving you the best of both security and simplicity.

Real-World Scenarios: Edge + VPN in Action

This isn’t just theory. Organizations across sectors are already leveraging edge intelligence and secure connectivity to modernize their operations.

Water Utilities

Operators can remotely monitor and adjust pumps, valves, and chemical dosing systems — even during inclement weather. Cellular fallback via Digi Axess VPN ensures that even if primary links go down, control stays online. The result? Fewer truck rolls, faster service restoration, and improved compliance.

Oil and Gas

In remote pipeline installations, Z45 controllers filter and act on data at the site, transmitting only actionable metrics back to HQ. This reduces bandwidth costs and improves operational visibility. And because Digi Axess VPN eliminates public IPs, operators can maintain strict security policies without compromising access.

In remote pipeline installations, Z45 controllers filter and act on data at the site, transmitting only actionable metrics back to HQ. This reduces bandwidth costs and improves operational visibility. And because Digi Axess VPN eliminates public IPs, operators can maintain strict security policies without compromising access.

Smart Manufacturing

Milliseconds matter on the factory floor. With local logic in the Z45, machinery can detect defects, adjust parameters, and alert operators instantly. Meanwhile, Digi Axess VPN provides engineers with secure, on-demand access to system logs and diagnostics — no VPN dongles or static IP configurations required.

Why It Matters Now

Cybersecurity concerns are growing. Skilled labor is increasingly decentralized. Infrastructure is expanding into more remote and rugged locations.

In this environment, companies can no longer rely on brittle networks and outdated control systems. They need edge-native tools that offer:

- Resilience when links go down

- Autonomy in the field

- Security without friction

- Scalability without cost inflation

The combination of Digi Z45 and Digi Axess VPN delivers all of the above — in a tightly integrated, easy-to-deploy package.

Conclusion: The Edge Isn’t the Future — It’s the New Standard

Industrial control is no longer just about automation. It’s about intelligence, security, and scale — at the edge. And it’s about doing more with fewer resources, less complexity, and greater confidence.

The Digi Z45 gives your infrastructure local brainpower.

Digi Axess VPN connects it securely to the people who need to see and manage it.

No public IPs. No downtime. No heavy IT burden.

This is industrial control reimagined: Smart at the edge. Secure by design. Scalable with Digi.

FAQ: How Edge Intelligences Supports Industrial Control

What is edge intelligence in the context of industrial control?

Edge intelligence refers to the integration of data processing, analytics, and decision-making capabilities at or near the source of data generation — typically on edge devices such as gateways, controllers, or embedded systems within industrial environments.

Instead of sending raw data to a centralized cloud for processing, edge devices analyze and act on data locally. This approach enhances responsiveness and reliability in control systems.

Why is edge intelligence important in industrial automation?

Edge intelligence provides key advantages for industrial control systems:

- Reduced latency: Enables real-time responses by processing data locally.

- Network efficiency: Limits bandwidth use by sending only relevant or summarized data to the cloud.

- Operational resilience: Maintains functionality even when Internet/cloud connectivity is lost.

- Enhanced security: Reduces exposure to cyberattacks by limiting external data transmission.

What are common use cases of edge intelligence in industrial control?

Some practical examples include:

- Real-time machine monitoring: Edge devices collect and process vibration, temperature, or torque data to detect anomalies or inefficiencies.

- Predictive maintenance: Local AI models predict equipment failure based on historical sensor patterns.

- Closed-loop control: Edge logic automates process adjustments based on immediate sensor feedback.

- Energy optimization: Edge algorithms adjust machine cycles or HVAC settings for energy savings.

- Quality control: Image or signal processing at the edge identifies defective products in real time.

How does edge intelligence interact with traditional SCADA or PLC systems?

Edge devices can:

- Augment PLCs/SCADA: By providing additional processing power or analytics not available in legacy systems.

- Bridge protocols: Translate and normalize data across protocols like Modbus, CAN, or Ethernet/IP.

- Push to cloud/enterprise: Filter and forward actionable insights from SCADA/PLC to MES/ERP systems or cloud platforms.

They often act as intelligent intermediaries between control-level systems and IT/cloud infrastructures.

What hardware is typically used for edge intelligence in industrial settings?

Common hardware includes:

- Industrial controllers: Hardened devices that combine the capabilities of programmable logic controllers (PLCs) and SCADA systems for industrial automation control.

- Industrial gateways: Rugged devices that combine connectivity (Ethernet, serial, cellular) with compute power.

- System-on-modules (SoMs): Embedded computing modules integrated into machinery or controllers.

- Single-board computers (SBCs): For prototyping or low-scale deployments.

- Smart sensors: Devices with built-in logic for signal processing and local control.

What types of software run on edge devices for industrial control?

- Real-time uperating systems (RTOS): For deterministic and fast response applications.

- Linux-based platforms: For more complex processing and containerized workloads (e.g., Docker).

- Industrial protocol stacks: Like MQTT, OPC UA, or EtherCAT.

- AI/ML runtimes: Lightweight inference engines like TensorFlow Lite, Edge Impulse, or custom C models.

- Remote device management tools: For over-the-air updates and diagnostics (e.g., Digi Remote Manager® or Digi Axess).

How does edge intelligence help with Industry 4.0 initiatives?

Edge intelligence enables the digitization and autonomy that underpin Industry 4.0 by:

- Supporting smart factories through real-time decision making.

- Enabling cyber-physical systems with autonomous control.

- Facilitating digital twins by synchronizing physical and virtual systems.

- Enhancing human-machine collaboration via responsive, adaptive machines.

What are some challenges to implementing edge intelligence in industrial environments?

- Integration complexity: Legacy equipment may lack compatibility with modern edge solutions.

- Security concerns: Edge devices must be hardened against physical and network-based attacks.

- Management at scale: Updating and monitoring hundreds of devices in the field can be challenging. A management platform that supports visibility and control across the deployment, like Digi Remote Manager® or Digi Axess, is crucial.

- Cost justification: ROI must be clearly demonstrated for industrial stakeholders.

Can edge intelligence reduce dependency on cloud services?

Yes. While cloud platforms are still valuable for long-term storage, analytics, and fleet-wide optimization, edge intelligence reduces dependence by:

- Performing local analytics and filtering

- Maintaining control logic during network outages

- Enabling fast feedback loops independent of cloud latency

This balance between edge and cloud is often referred to as hybrid edge-cloud architecture.

What industries benefit most from edge intelligence in control systems?

Next Steps